Introduction

The proIMS production suite includes building blocks to configure comprehensive Third-Party-Access (TPA) software solutions.

TPA solutions worldwide differ widely based on customer requirements, TPA -policies, shipper data, production capabilities, transportation networks or storage possibilities. There are several solutions on the market which represent on single solution for one specific customer. Unlike these monolithic applications the proIMS suite is structured in flexible, configurable building blocks which can build a customized TPA application or used as a part of it.

The drawing shows the different components of a TPA based gas network.

On one side are Production facilities which build the entry point of the network. Each production can produce a certain amount of gas with a certain quality over a specific time period. Input of the software is a production plan of each entry point including maintenance downtimes or seasonal different production capabilities.

The transportation network is divided in certain balance areas. Each balance area consists of pipelines, compressor stations and relevant valves. Shippers can bid for a certain amount of gas, which they want to book for a specific time period.

The TPA software must have the capability to calculate a production forecast plan based on the technical and hydraulic capabilities of the network and the bids of the shippers.

Besides the line pack of the pipelines some networks have external storage capabilities like gas underground storages or even LNG plants, to balance demand and production capabilities in a more flexible way. This must be taken under consideration when the production forecast plan is calculated.

The production forecast plan is base for the network operation and calculates the setpoints for the network operation. The operation must be supervised in real time in order to ensure that the exit points of the network deliver to the customer the agreed amount of gas and quality based on the shipper contracts. If the production system does not meet the agreed production conditions management and operators needs to be alarmed. Besides this a TPA software must have the capability to calculate possible what if scenarios, in order to get new setpoints which covers the problem.

Architecture

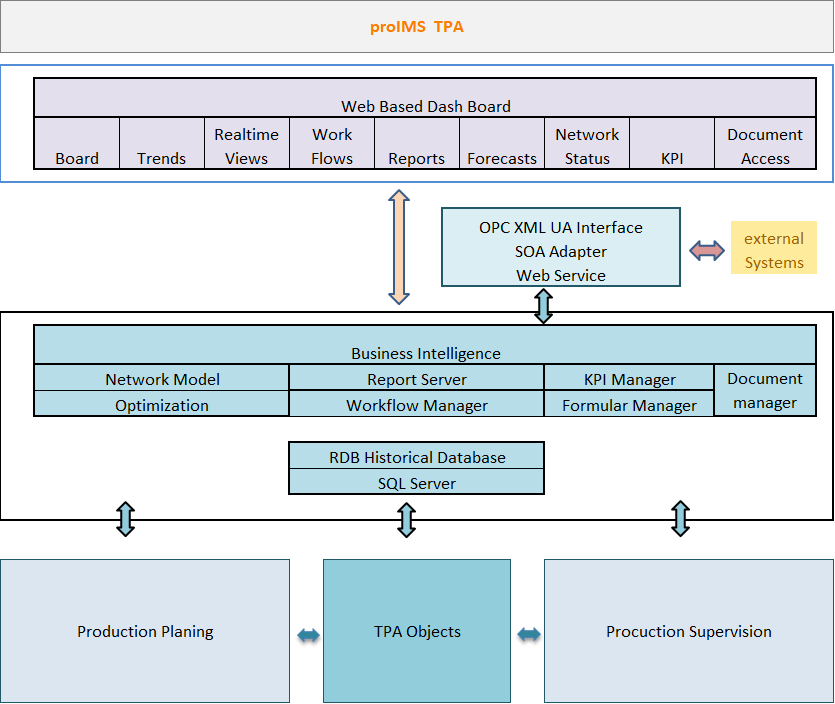

The proIMS production suite includes building blocks which cover the requirements of all aspects of a TPA system. It consists modules for production planning, production supervision, web access of the data and interfaces with other systems.

All building blocks are an integrated part or the proIMS suite and can be divided in:

- TPA Objects (proIMS Data Objects for TPA systems)

- Production Planning Modules to support the shipper bidding process, evaluate contracts and create a final production plan for a certain time period.

- Production Supervision Modules to created setpoints for the production and supervise the production in real time, if they meet the contracts.

TPA Objects

The following table shows a simplified model of the Objects, which are used to create TPA applications.

The proIMS Suite uses an industry 4.0 MES object format, which enables the user to adapt the object format freely to the needs of the real application. Once the object is defined it will be used in all parts of the suite (calculation and web modules) in a unique manner.

It should be mentioned that a TPA system needs sufficient technical data like:

- Network architecture

- Network hydraulics

- Storage Characteristics

- Technical Data of compressors and control valves

- Configuration of metering skids

- Flow Regimes

- Measurement equipment

- Metering Skids

- Chromatographs/ Lab Data

For production supervision all relevant flows, pressures, temperatures, valve status and gas compositions must be measured and available in real time.

Production Planning

The drawing shows the building blocks used for production planning.

The building blocks support two work flows:

- Contract Management

- Production Planning

The first step is contract management.

First all bids of authorized shippers are verified against TPA policies.

The bid verification module is a small expert system, which includes all rules which must be considered.

After verification all bids and relevant contracts are evaluated if the network is able to handle the bid based on the production capabilities of the entry points and transportation network.

If case the demands of all bids and current contracts exceeds the network capabilities a linear optimisation can be triggered, to determine the most economically solution.

In a second work flow the production forecast is determined for a certain time period which is the input for the later gas production.

Production Supervision

The drawing shows the building blocks used for production supervision.

In opposite to the production planning module the production supervision process is base on real time calculations RTC.

The network supervisor module interacts with the operator to generate setpoints for the network to meet the production plan. Normally this is an open loop application which enables the operator to do the final decisions.

The network balance module steadily supervises the current production figures if they meet the production plan. The process is connected to a real time database, which gets the actual signal vales from the process. If the network does not meet the actual requirements operator and management will be alarmed. Before setting new setpoints to cover the problem the operator can use predefined What IF scenarios to verify his decisions.

Finally, the actual production figures can be used for accounting.