Purpose of this documenet

Purpose of this document is to describe the proIMS Training Server.

The proIMS Training Server is part of the proIMS production framework.

The proIMS production framework is a production suite, to configure process related management information systems.

The proIMS Training Server is a composition of products of this suite. For a detailed description of the used components refer the document: proIMS_Framework.

The proIMS Training Server can be used for training models in for the following areas:

- oil and gas facilities

- pipelines

- water systems

- well heads

- hydro power plants

- nuclear power plants

Overview

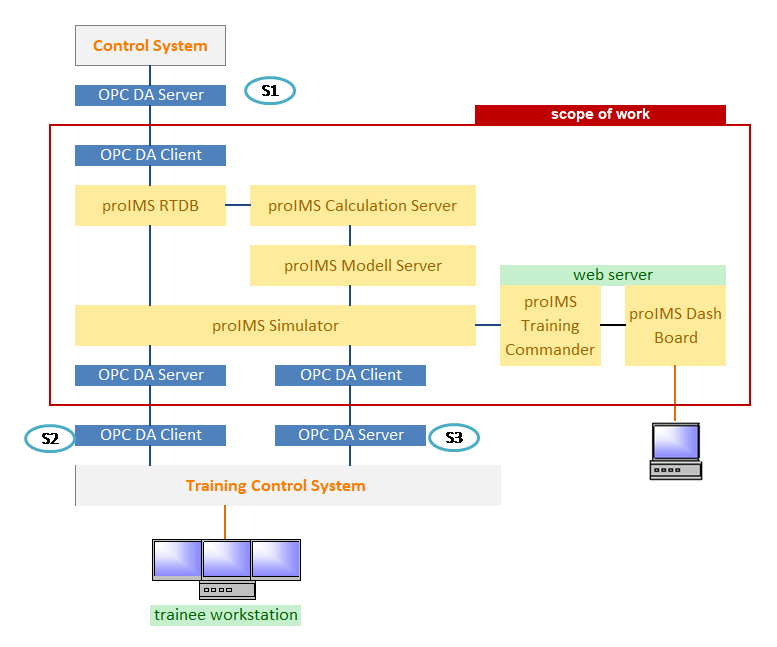

The following drawing shows the architecture of the proIMS Training Server.

Figure 1 proIMS Training Simulator Architecture

The training server is made up of components of the proIMS product lines. The following products are used:

- proIMS RTDB Real Time Data Base

- proIMS Calculation Server

- proIMS Modell Server

- proIMS Simulation Server

Functioning

The central RTDB has the following tasks:

- store process data from the real process

- store process data calculated from the look ahead simulation

- store the models

- store the configuration of the training server

Real process data can be obtained via an interface (S1) to the process control system that controls the process. Based on this data snap shots of real process states can be created. These snap shots are the base for the simulation. Based on a certain snap shot the complete process can be simulated by the calculation server. The calculation server is feed with equations defined by process models...

The models handling itself is task

The model server includes a set of mathematical equations adapted to the underlying process.

proIMS has libraries for the following facilities and processes:

- oil and gas facilities

using proIMS Hydrocarbon Production Optimization and Simulation - pipelines

using proIMS Pipeline Management - water and reservoirs

using proIMS Water - well heads

using proIMS Well Head Modeling and Simulation - hydro power plants

using proIMS plant Management and proIMS energy - nuclear power plants (containment simulation)

using proIMS plant management proIMS nuclear power

The proIMS Modell server consists of one or more of these libraries and of a PLC simulator for logic simulation to simulate shut down sequences or other PLC based logic sequences.

Training Modell

The training simulator calculates the plant parameters corresponding to particular conditions and displays these parameters on the training station of the control, system. The model server simulates the process and the behavior of the process equipment. The calculated values feed the training control system with the actual process values. The training simulator does not simulate the logic and control loops of the control system. If the interface between model server and the control system is well designed an experienced operator will not notice a significant difference between the model and the process itself.

The training model includes also PLC simulation software, to simulate the control system of local process components such as compressors or pumps.

The training server transmits in real time calculated values to the training control system using an OPC interface (S2). It receives commands and set points via a second OPC connection (S3).

Training Commander

The training commander is used to configure the training models and to guide the trainee during a training session. The interface for configuration and trainee guidance is completely web based and integrated to the proIMS dashboard.

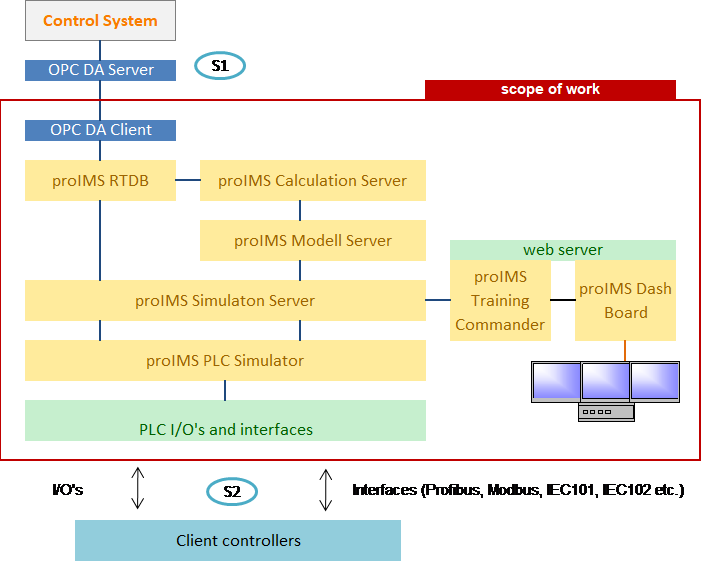

Integrated PLC Application

In some applications it is necessary to feed the client controllers directly with physical outputs and receive the inputs of the external control logic.

The following drawing shows the concept.

With the proIMS module PLC Simulator external control logic can be simulated and via PLC interface boxes directly connected to client controls system.

In this case the IO interfaces simulate the behavior of the process and create the IO’s like the real process would create it. This can be used for training purposes or for test of new controller software for mission critical applications.

Figure 2 proIMS Training Simulator with IO connection to external controllers